|

| |

Diener Femto Plasma Etcher

Femto Version A.

|

A plasma is an ionized gas such as is used in fluorescent lamps. Typically a high electric field is used to strike a plasma. Electrons are accelerated in this field and they strike atoms or molecule that then become ionized. The atoms or molecules are then also accelerated in the electric field. The atoms and molecules collide with each other and through the collisions can enter an electronic excited state. The excited atom or molecule can decay to the ground state by emitting a photon.

The energetic atoms and molecules in a plasma can bombard surfaces in the plasma and can clean or etch these surfaces. Read the Plasma Technology - English (pdf) ≈

Plasmatechnik - Deutsch (pdf) for more information on the uses of plasmas.

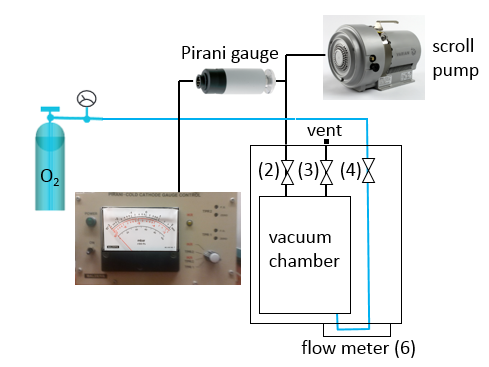

The plasma system at the Institute of Solid State Physics is a Diener Femto Version A. The vacuum chamber is pumped with a Varian scroll pump and the pressure is measured with a Balzers TPR 010 Pirani gauge. The Pirani gauge is connected to the TPR2 port of a Balzers PKG 020 controller. The plasma in generated by applying a 40 kHz voltage to the electrode. A schmatic of the system is shown below.

Operating Instructions

|

- Turn on the main power of the plasma etcher (1). This turns the scroll pump on.

- Switch on the pressure gauge contoller. The Pirani gauge, TPR2, should be selected.

- Check the switch settings on the front of the Femto. They should be:

- Pump valve (2): Off

- Gas valve (4): Off

- Generator (5): Off

- Ventilation (3): On

- Open the vacuum chamber by removing the lid with a slight rotation (9).

- Put the samples into the vacuum chamber.

- Attach the lid to the vacuum chamber (9).

- Close Ventilation valve (3) (light should turn off).

- Open the pump valve (2).

- Wait until pressure reaches 0.2 mbar. Read the upper (logarithmic) scale of the pressure gauge controller. It takes about 5 minutes to reach this pressure.

- To etch with oxygen:

- Twist open the valve on the top of the oxygen tank.

- Open the gas valve (4) on the front panel of the Femto.

- Set the required throughput (6), wait until equilibrium pressure is reached (at least 1 minute); Recommendation: throughput 8-10, pressure ca. 0.15 – 0.2 mbar

- Switch off the pressure gauge.

- Set the required ‘plasma strength’ (8); Recommendation: weak plasma: 4.0, strong plasma: maximum value.

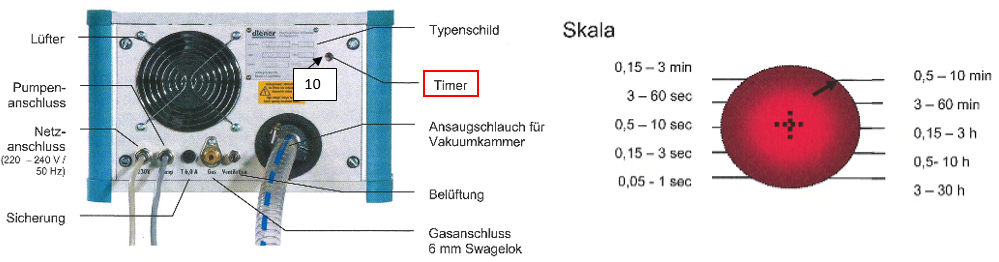

- Set the etching duration. A timer can be set for times between 0.05 seconds and 30 hours. The switch to set the timer scale is inconveniently placed on the back side of the instrument. (10)

The Timer dial on the front (7) can then be used to adjust the time within the selected range. The time cannot be set very precisely this way. Some measured times are given in the table below.

0.5 - 10 minutes |

| Scale | Duration |

| 1.00 | 1 min 30 s |

| 5.00 | 6 min 15 s |

| 7.00 | 10 min |

| 9.00 | 12 min |

|

- Switch on the plasma-discharge (5). The timer will stop automatically the plasma automatically after the programmed time has elapsed.

- After the etching process, switch off the gas flow (4).

- Close the valve of the oxygen tank.

- Vent the vacuum chamber (3) (the light is on when it is vented)

- Remove the samples. Be careful, they may be hot.

- Turn off the main power of the plasma etcher (1), this also turns off the scroll pump.

http://lampz.tugraz.at/~hadley/semi/ch9/instruments/Diener/femto.php

|